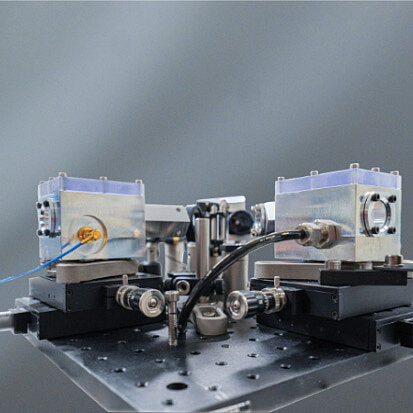

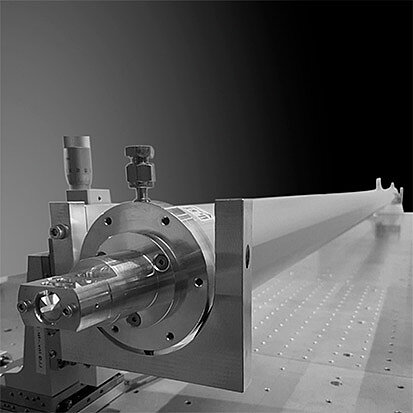

Single-shot measurements of CEP

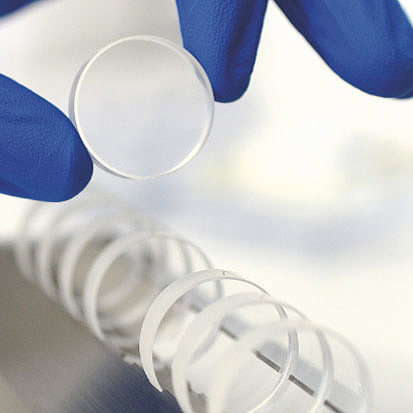

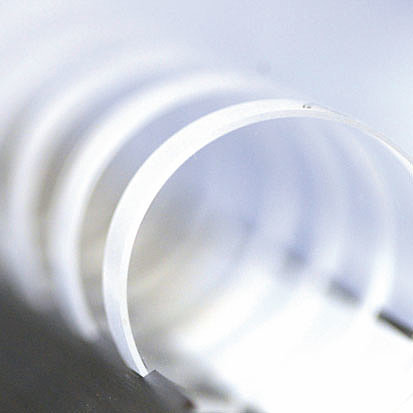

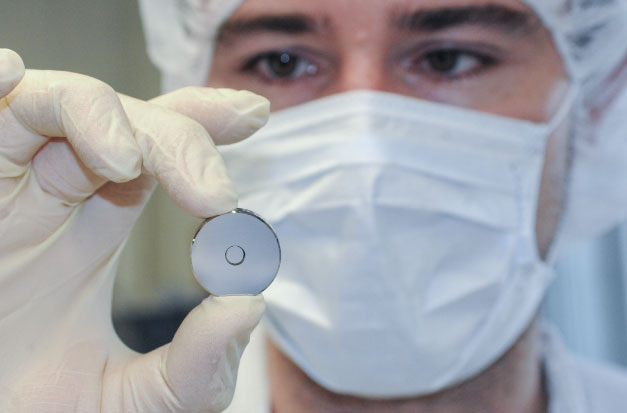

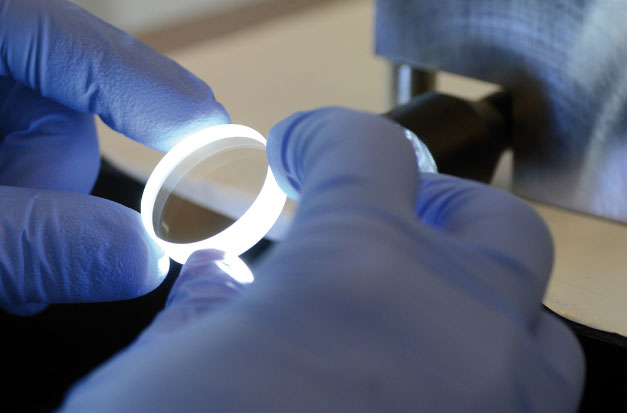

Optics Manufacturing

Coating Facilities

UltraFast Innovations has three different coating facilities at its disposal, thus offering the coating technique that best suits your requirements.

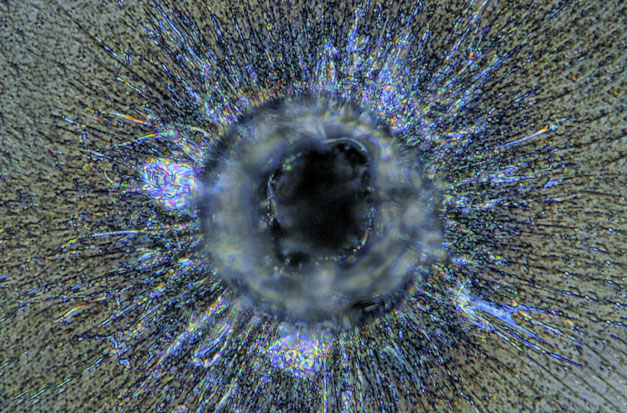

Laser Induced Damage Threshold (LIDT)

A brief introduction into the topic of laser induced damage in ultrafast regime and measured reference values for our products.

Clean Room

We are proud to have clean room facilities of Class 100 (ISO4). Our coating machines HELIOS and SYRUS are installed in this cleanroom.

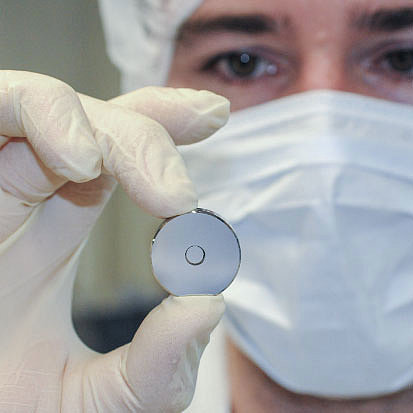

Optics characterization and quality control

The following tools are available at UltraFast Innovations to verify the outcome of the coating process. Optics can be characterized with regard to their reflectivity, dispersion, surface quality and damage threshold. For the most challenging optics designs we will perform test coating runs before the actual coating.

Optics consulting and design

Designing customized optics is a process that demands deep knowledge in the production as well as the application of optics. At UltraFast Innovations, we can offer you both: upon first contact, we will provide consultation on your optics problem. Be your application industrial or scientific, our experimental knowledge helps us to find the most suitable solution to fit your needs.

Featured Products